Jireh STIX – Flange Scanner

In-Service Flange Inspection

Have questions about buying this product?

The STIX – Flange Scanner is used for a variety of flange coupling inspection applications such as flange face corrosion. Carry one or two phased array probes straight around the flange with the included guiding system while outputting encoded positional feedback to any UT instrument. Magnetic wheels adhere to ferrous surfaces and the articulating frame design allows placement on diameters as small as 7.6 cm (3 in).

Brake

Lock the position of the scanner in place by activating the brakes.

Flange Scanner Guides

Maintain a straight scan path around the flange utilizing the adjustable guides included with the scanner.

Handle

A safe contact point for the user to control the scanner.

Spring-Loaded Encoder

The spring-loaded encoder maintains constant encoder wheel contact with the scan surface for precise tracking.

Diameter Indicator

Configure the scanner to various diameters using the indicator.

Magnetic Wheels

Dual magnetic wheels keep the scanner mounted to the scan surface even upside down.

Kit Contents

SCANNER

STIX Flange scanner with 8 magnetic wheels

PARTS & ACCESSORIES

Spring-loaded encoder

4 mm ID irrigation kit (7/16 in Quick Connect)

Probe holder spare parts kit

Cable clips

User manual

Rugged carrying case

TOOLS

3 mm hex driver

Wrench for pivot button adjustment

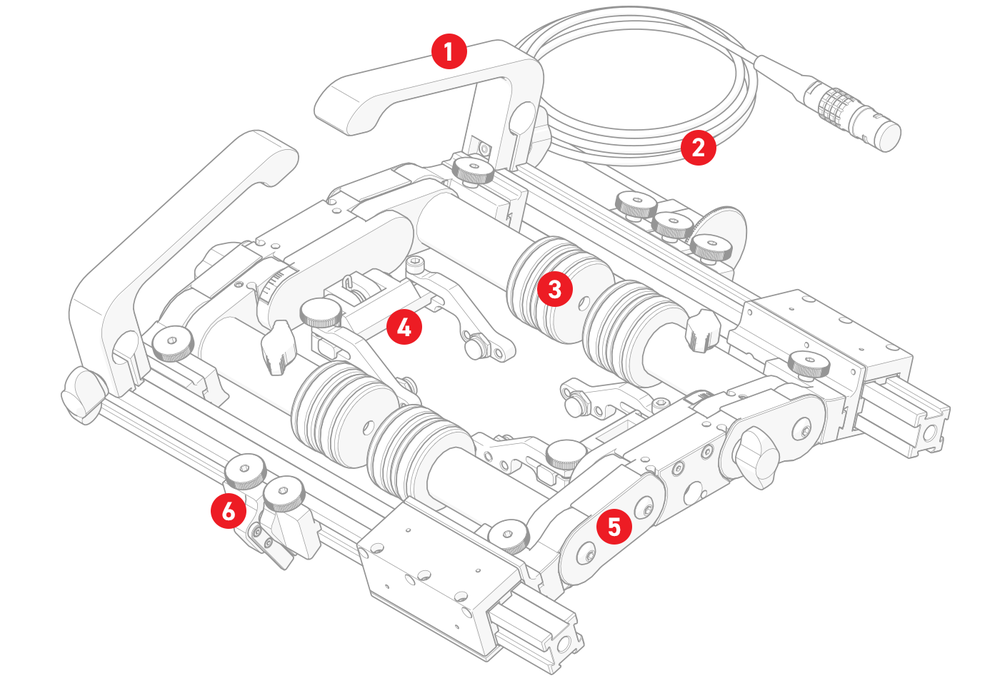

Component Identification

1 Handles

Position the dovetail handles along the frame bar for optimal control.

2 Spring-Loaded Encoder

The spring-loaded encoder is fully compatible with all standard instruments.

3 Magnetic Wheels

The magnetic wheels are coated with urethane to reduce the effects of foreign debris obstructing the scanner motion. Two sets of 4 magnetic wheels are included with the system to provide optimal magnetic attraction during scanning operations.

4 Spring-Loaded Probe Holders

Simplified probe holder carries probe/wedges with ease.

5 Articulating Frame

The design of the frame allows scanning flanges as small as 7.6 cm (3 in).

6 Flange Scanner Guides

The guides ensure the scanner travels straight around the flange.

GENERAL

Pipe Range: 7.6 cm (3 in) to flat

Encoder Resolution: 9.05 counts/mm (230.0 counts/inch)

Probe Holding Capacity: 2 phased array wedges

Encoder Cable Length: 5 m (16.4 ft)1

Inspection Surface: Ferrous materials

RADIAL CLEARANCE

With Handles: 9.7 cm (3.8 in)

Without Handles: 4.1 cm (1.6 in)

SIZE & WEIGHT

Frame Height: 10 cm (3.9 in)

Frame Width: 28 cm (11 in)

Frame Length: 29.8 cm (11.7 in)

Frame Weight: 2.4 kg (5.3 lb)

ENVIRONMENTAL SPECIFICATIONS

Operating Environment: -20°C (-4°F) to 50°C (122°F)

Environmental Sealing: Watertight (submersible), Contact JIREH for details

PROBE CENTRE SPACING

Minimum: 1.8 cm (0.72 in)2

Maximum: 6.4 cm (2.5 in)2

SPRING-LOADED PROBE HOLDER SPECIFICATIONS

Minimum Wedge Width: 31 mm (1.2)

Maximum Wedge Width: 41 mm (1.6 in)

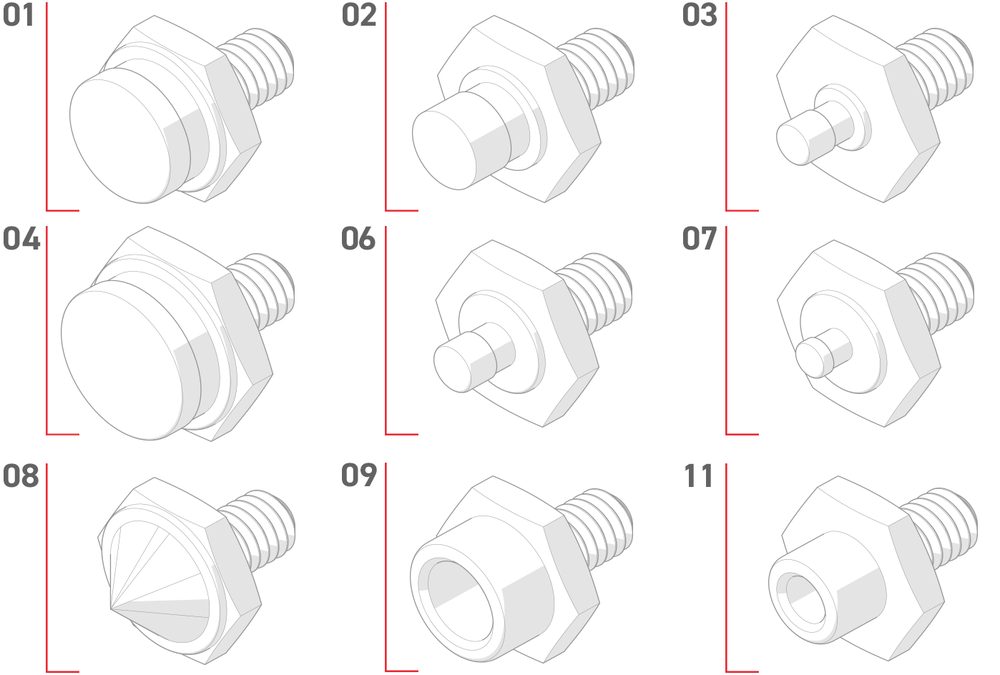

Probe Holder Pivot Buttons

01

Pivot Hole Size: 8.0 mm (0.315 in)

Wedge Type: Olympus PA

Hex Size: 9.53 mm (3/8 in)

02

Pivot Hole Size: 5.0 mm (0.197 in)

Wedge Type: Olympus TOFD, Olympus A27 DMA

Hex Size: 9.53 mm (3/8 in)

03

Pivot Hole Size: 2.7 mm (0.106 in)

Wedge Type: Sonatest DAAH PH

Hex Size: 9.53 mm (3/8 in)

04

Pivot Hole Size: 9.5 mm (0.375 in)

Hex Size: 11.1 mm (7/16 in)

06

Pivot Hole Size: 3.0 mm (0.118 in)

Hex Size: 9.53 mm (3/8 in)

07

Pivot Hole Size: 2.3 mm (0.09 in)

Hex Size: 9.53 mm (3/8 in)

08

Pivot Hole Size: Conical Head

Hex Size: 9.53 mm (3/8 in)

09

Pivot Hole Size: 5 mm (0.197 in)

Wedge Type: Internal Zetec PA/TOFD, Phoenix TOFD

Hex Size: 9.53 mm (3/8 in)

11

Pivot Hole Size: 5.6 mm (0.221 in)

Hex Size: 9.53 mm (3/8 in)

- Custom encoder cable lengths are available.

- Probe centre spacing dimensions are based on Olympus SA10 wedge.

Technical specifications subject to change.