ОKО-22М-UT ultrasonic flaw detector

Have questions about buying this product?

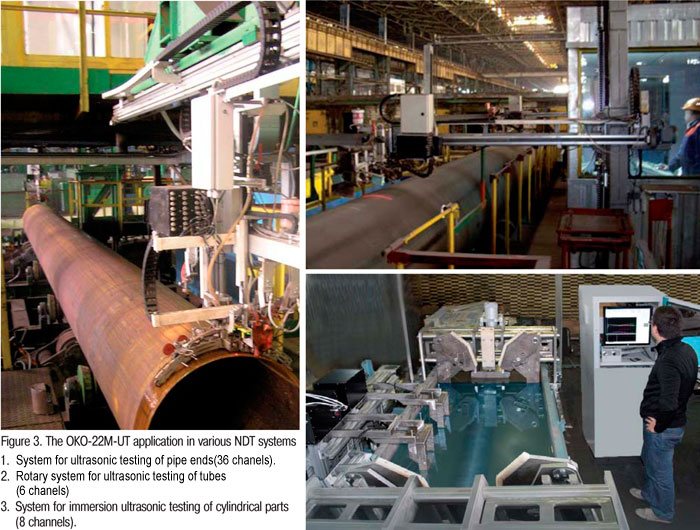

The ОКО-22М-UT ultrasonic flaw detector is a standalone electronic unit. It is intended for application in high-performance automated multi-channel NDT Systems, transportable systems (mechanized NDT systems) or for manual testing.

Application of the ОKО-22М-UT ultrasonic flaw detector

It is available in several flaw detector models that differ in the number of channels and in the volume of built-in functions for result processing.

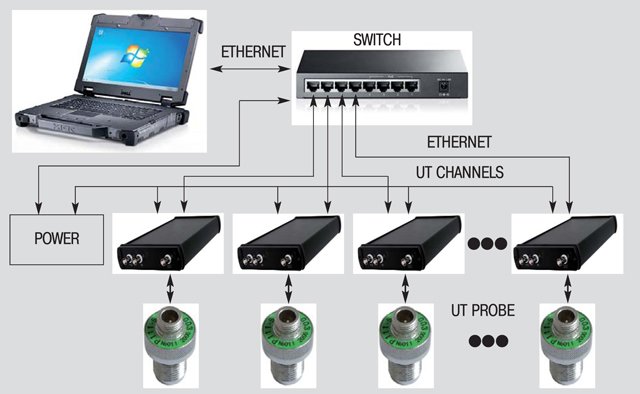

As the flaw detector is designed in a form of a standalone device with the connection to the PC via the Ethernet port, several UT channels can be connected to the PC via the Switch unit. This enables creating UT multi-channel testing systems.

Technical capabilities of the flaw detector allow using it both in online and offline testing systems of stationary type.

APPLICATION OF ULTRASONIC TESTING TECHNIQUE IN VARIOUS INDUSTRIES:

| Production sector, test object | Regulatory Documentation | Required number of channels | Operating frequency, MHz | Testing techniques |

| Metallurgy, testing the flat rolled steel | EN10160, ASTM 578/A578M-96, A435A, ISO 12094 | 60-100 | 2-5 | Immersion or contact |

| Metallurgy, testing the rolled round steel bars | EN 10308, EN 10228-3, ASTM E – 2375, MS-STD – 2154 | 3-20 | 2-10 | Immersion or contact, testing velocity is up to 2 m/s |

| Engineering, testing the pipe welded joints | API 5L, API5 CT, EN 10246-17 | 12 | 2-5 | Immersion or contact, velocity is up to 2 m/s |

| Engineering, testing the pipe body, thickness gauging | API 5L, API5CT, EN 10246, ASTM E1816-96 | 56 | 2-5 | Immersion or contact, velocity is up to 1 m/s. Resonance-frequency technique for measuring the pipe wall thickness – from 0.2 to 5.0 mm. |

Figure 1 – UT channel “ОКО-22М”

Figure 1 – UT channel “ОКО-22М”

Figure 2 – Structural scheme for connecting the UT channels

Figure 2 – Structural scheme for connecting the UT channels

Parameter | Value |

PULSER | |

| Pulse mode | Spike pulser, Square-Wave pulser |

| Pulse Voltage (SQ mode) | 120-300 V in steps 10 V with tolerance 10% |

| Pulse falling/rising time | 5 ns |

| Pulse Width (SQ mode) | 20 – 500 ns in steps 10 ns with tolerance 10% |

| PRF (SQ mode) | 15 – 2000 Hz in steps 5 Hz, 3 automatic modes: Auto Low, Auto Med, Auto High, Manual |

| Pulse Voltage (spike mode) | Low (100 V), High (400 V) |

| Pulse energy (spike mode) | Low (30 ns), High (100 ns) |

| PRF (spike mode) | 15 – 8000 Hz in steps 5 Hz, 3 automatic adjustment modes: Auto Low, Auto Med, Auto High, Manual |

| Damping | 50, 62, 150, 400 |

RECEIVER | |

| Gain | 0 to 110 dB adjustable in steps of 0.2, 0.5, 1, 2 dB |

| Receiver input impedance | 400Ω±5% |

| Receiver bandwidth | 0.2-27 MHz (- 3 dB) |

| Digital filter setting | Eight digital filter sets standard (0.2-10 MHz; 2.0-21.5 MHz; 8.0-26.5 MHz; 0.5-4 MHz; 5-15 MHz; 5-15 MHz; DC-10 MHz ) |

| Rectification | Fullwave, positive halfwave, negative halfwave, RF |

| Amplitude measurement | 0-110% |

| Reject | 0-80% FSH |

| Units | Millimeters, inch or microseconds |

| Range | 1 to 6000 mm |

| Velocity range | 1000 to 10000 m/s in steps of 1, 10, 100, 1000 m/s |

| Thickness measurements range | 0.6 to 6000 mm |

| Probe angle | 00 to 900 in steps 0.10, 1.00, 100 |

DIGITAL SPECIFICATION | |

| ADC | 10 – bits with the sampling rate 100 MHz |

| A-Scan buffer | 8 KB |

GATE | |

| Measurements gates |

|

| Start Gate | Variable over entire range |

| Width Gate | Variable over entire range |

| Gate height | Variable from 2 to 100% FSH |

MEASUREMENT SPECIFICATION | |

| Result display | A-scan, B-scan, C-scan, D-scan, TOFD scan |

| DAC/TCG |

|

| DGS |

|

CONNECTORS | |

| Probe connector | 2 BNC or 2 Lemo 1S |

| USB port | USB-2.0 |

| Ethernet | + |

| Alarm output | + |

| Encoder | 1 Lemo (with the option of two encoders operation) |